Stainless Steel Double Card Pipe Repair

Support Customized Processing

Stainless steel double belt repair clamp-an advanced solution to solve the leakage and fracture of the water pipe system. This repair clip is made of high-quality stainless steel, durable and corrosion-resistant, and is designed to provide the best pipeline repair solution. The dual strap design provides superior support, stability and enhanced sealing to ensure your water system is safely in place.

MOQ:

1000

- Commodity name: Stainless Steel Double Card Pipe Repair

Support:

hgxs@hbhuagen.com

- Product Description

-

Stainless steel double belt repair clamp-an advanced solution to solve the leakage and fracture of the water pipe system.

Manufacted from high quality stainless steel, this repair fixture is durable, corrosion resistant, and designed to provide optimum pipe repair solutions. The dual strap design provides superior support, stability and enhanced sealing to ensure your water system is safely in place.

The clamps are available in different sizes, making it a perfect fit for pipes of different diameters, making it a versatile and ideal choice for businesses and homeowners. The easy-to-install fixture is designed to work effectively under high pressure, providing a fast and effective solution for maintenance.

Sealing leaks and breaks can be quite expensive, but with the stainless steel double band repair clip, you can avoid unnecessary expenses and restore your plumbing system in no time. The clamp can handle a wide range of pipeline pressures, making it perfect for applications in water supply networks, petrochemical facilities, industrial plant operations, and other applications.

The fixture is designed to meet specific industry standards to ensure the highest quality and durability, making it an essential purchase for pipeline professionals and DI Yers.

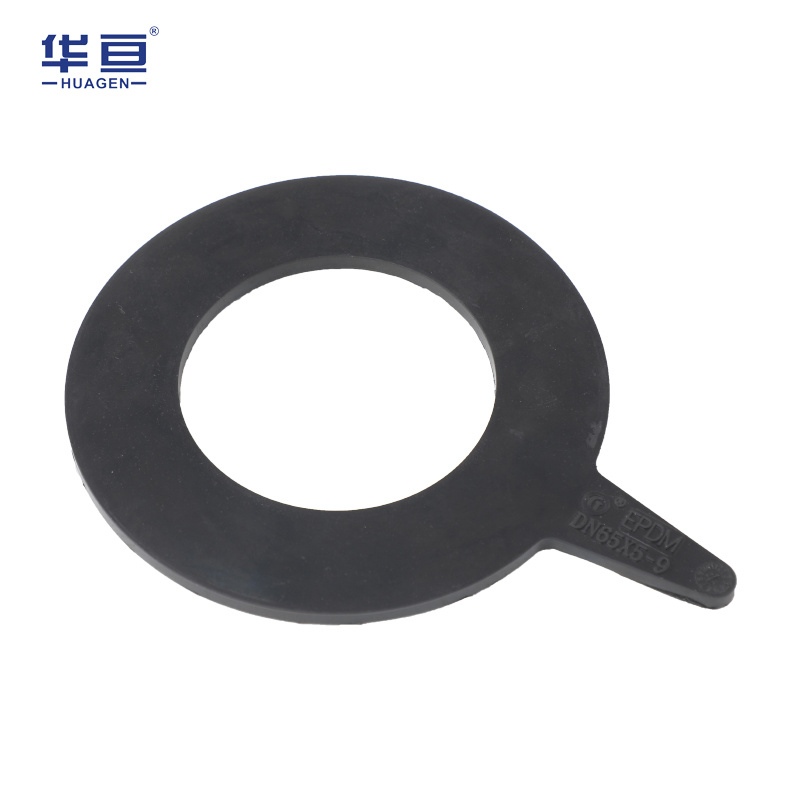

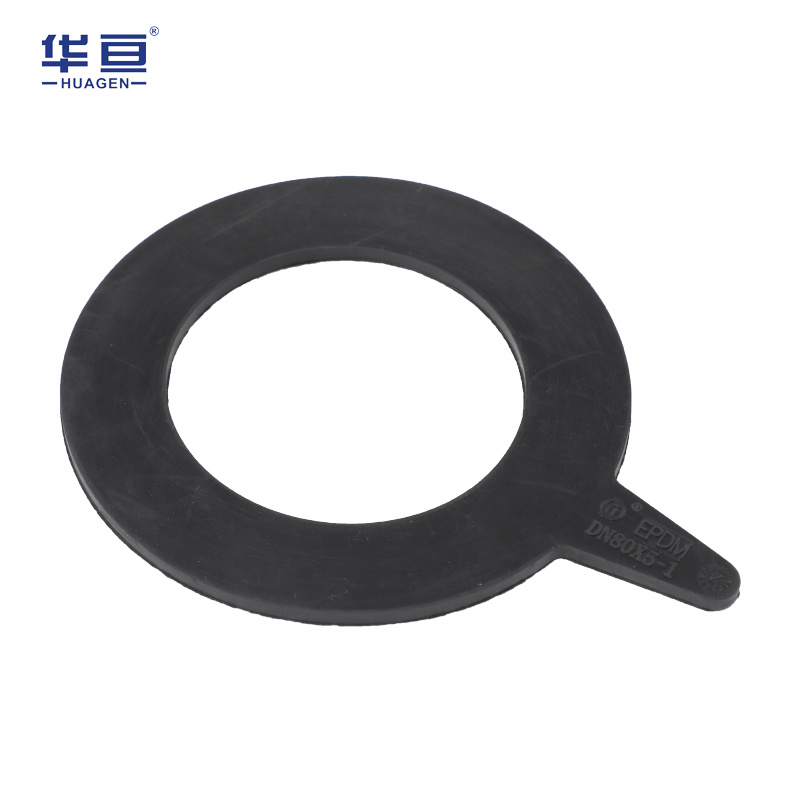

The stainless steel double belt repair fixture is a fixture used to repair pipeline leaks or breaks. It consists of two stainless steel bands that are joined together with bolts and nuts. A clamp is placed over the damaged area of the pipe and tightened to form a seal that prevents further leakage. The double belt design provides additional strength and stability to the fixture, making it suitable for larger pipes or high pressure applications. Stainless steel is a durable and corrosion-resistant material, making the fixture suitable for use in harsh environments. Double band repair clamps are commonly used in the oil and gas industry, water treatment plants and other industrial applications.

Features

1. Simple installation;

2. It is completely constructed of 304/316 stainless steel, which has high corrosion resistance;

3. Full round nitrile rubber gasket;

4. Each fixture is suitable for multiple pipe diameters;

5. Can be installed on the pressurized main pipe;

6. Able to adapt to pipe irregularity or ovality;

7. Full passivation;

8. Provide plastic thread protector;

9. Sharp surface, to avoid injury to the installation personnel;

10. Minimum downtime of the affected power supply;

11. Molybdenum key plus fasteners to prevent scratches;

12. Suitable for most pipe types and sizes;

13. Shipment with installation instructions;

14. Manufactured according to ISO 9001 quality standard.

Production Workshop

Company development direction: Strive to become a leader in specialized manufacturing and technological innovation of sealing products for water and thermal pipelines in the pipeline interface sealing industry.

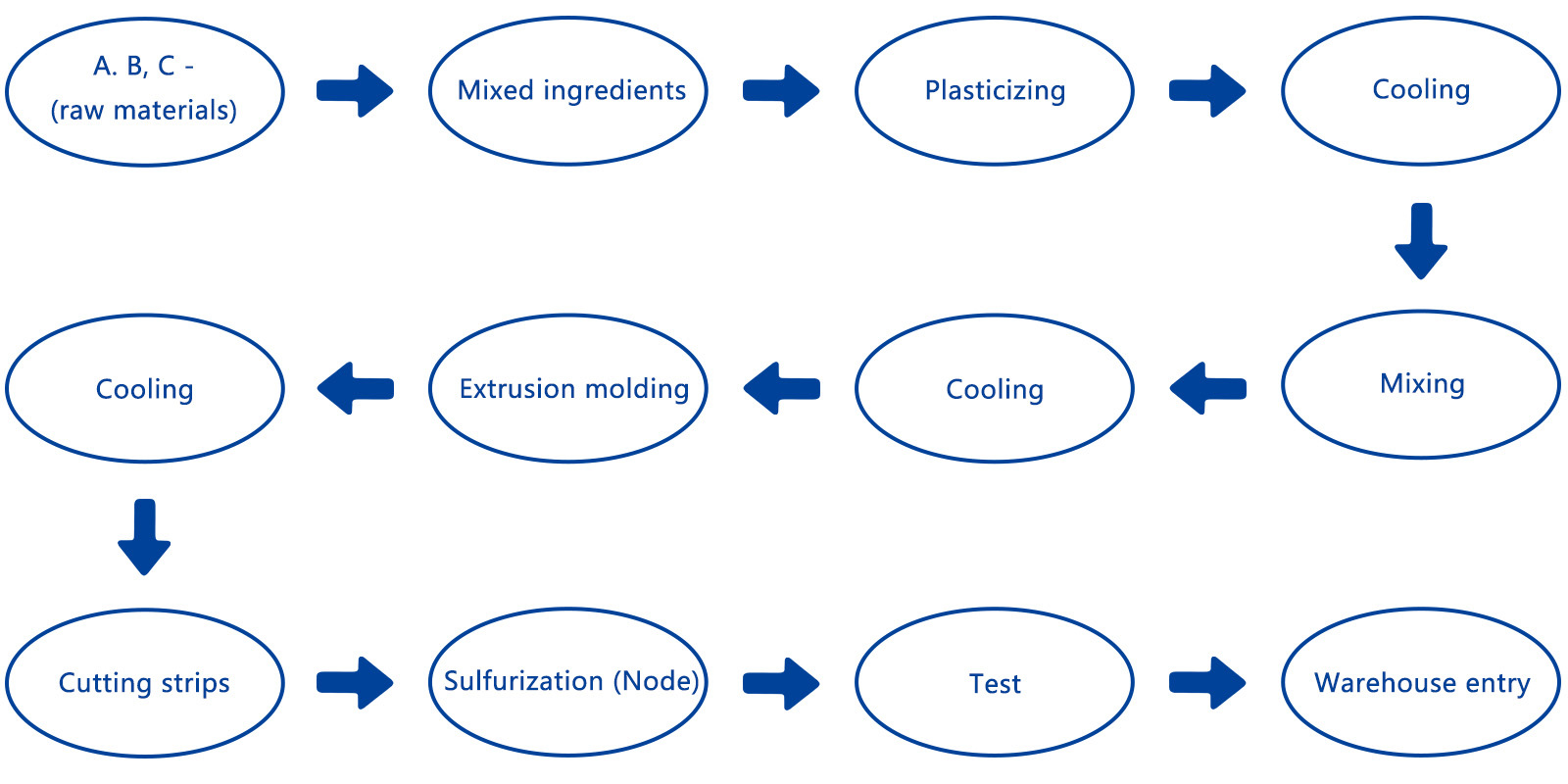

Production Process

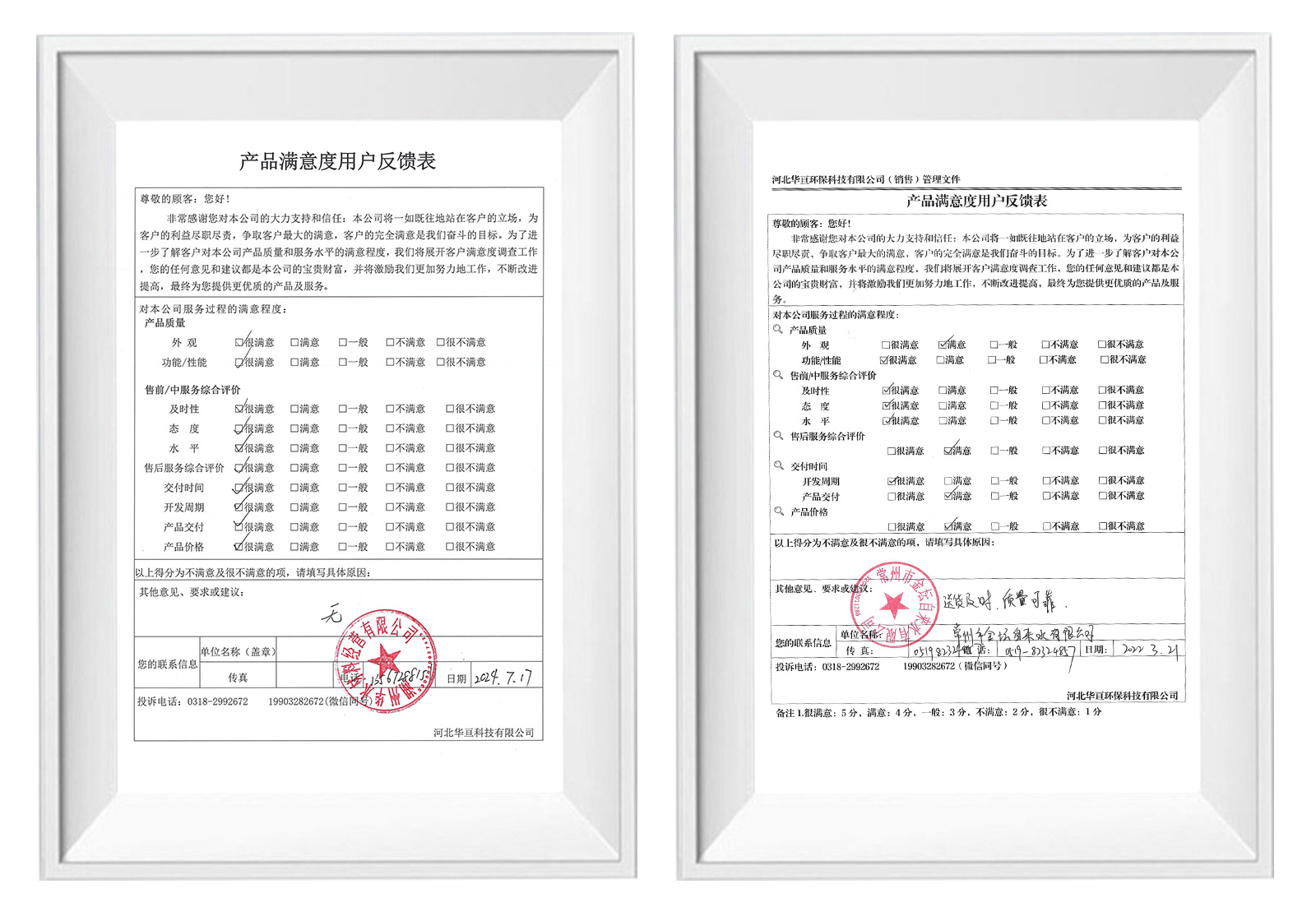

Qualification Certificate

Buyer Reviews

Engineering Case

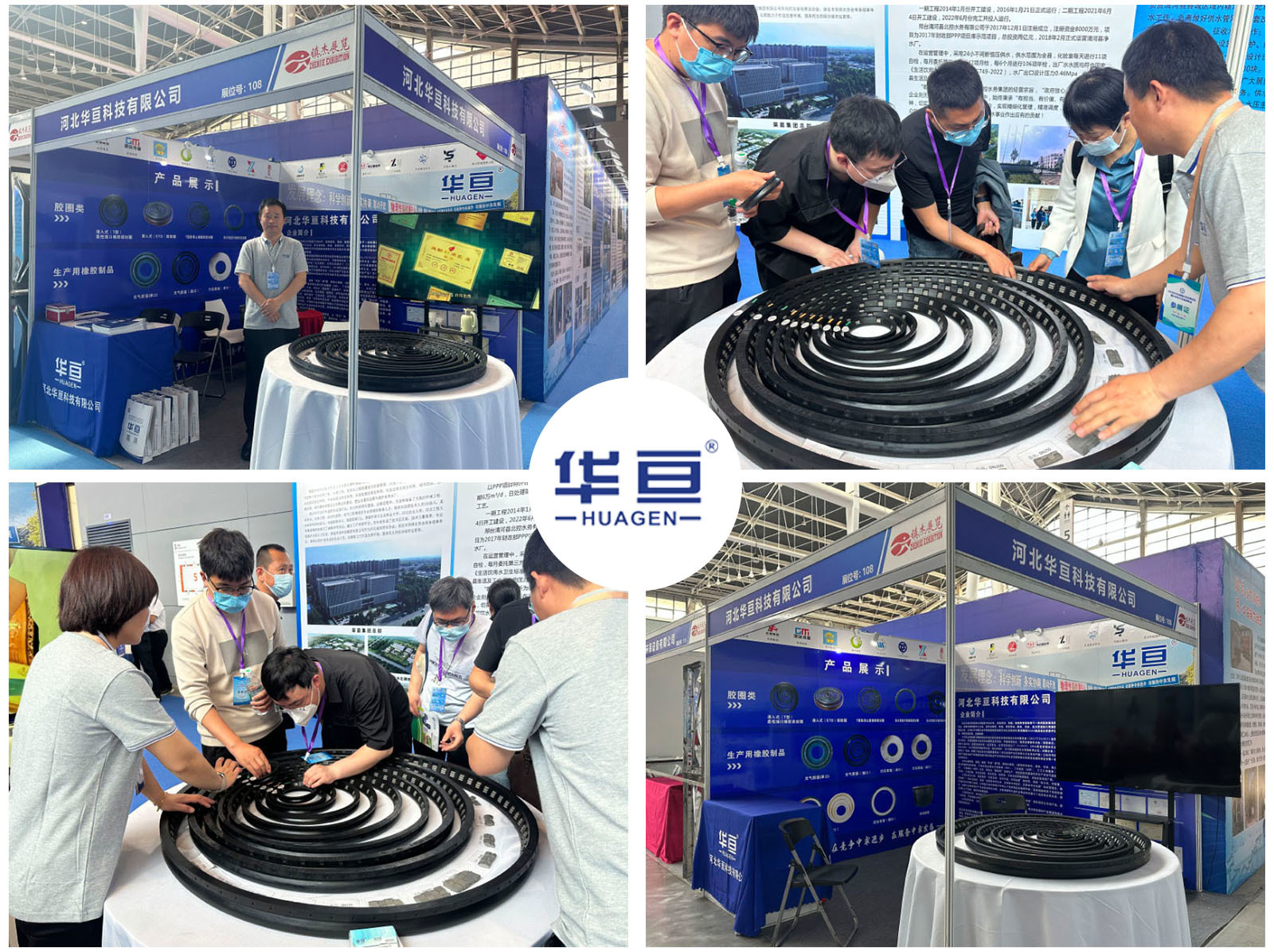

Exhibition Team

Logistics Delivery

Factory Panorama

Application Scenarios

Common Problem

★ 1. Cracks and fractures: Rubber rings may experience cracks and fractures during use due to stress or aging.

The treatment method can be to repair or replace rubber rings with cracks and fractures. Rubber patches or glue can be used for reinforcement during repair.

★ 2. Deformation and hardening: Rubber rings may undergo deformation and hardening when used for a long time or exposed to external environments such as high temperatures and chemicals.

The solution can be to replace the deformed and hardened rubber rings. In addition, appropriate maintenance measures can be taken, such as avoiding exposure to extreme temperatures and using suitable lubricants, to extend the service life of the rubber ring.

★ 3. Corrosion and aging: Rubber rings can experience corrosion and aging after prolonged use or exposure to corrosive effects such as chemicals and oxygen.

The solution can be to replace the rubber rings that have corrosion and aging. In addition, appropriate maintenance measures can be taken, such as storing in a dry, cool, and well ventilated environment, to extend the service life of the rubber ring.

★ 4. Friction damage: Rubber rings may experience friction damage when in contact or friction with other hard objects.

The treatment method can be to repair or replace the rubber ring with friction damage. Rubber patches or glue can be used for repair.

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!