Ductile iron overall four-way

Support Customized Processing

All our ductile iron cross flanges are the perfect solution for your piping needs. Our products are made of the highest quality materials to ensure durability and strength, and can withstand even the harshest conditions.

MOQ:

1000

- Commodity name: Ductile iron overall four-way

Support:

hgxs@hbhuagen.com

- Product Description

-

All our ductile iron cross flanges are the perfect solution for your piping needs. Our products are made of the highest quality materials to ensure durability and strength, and can withstand even the harshest conditions.

Our fully flanged cross design is easy to install and maintain, making it a time and cost-effective choice to meet your piping needs. With a range of sizes and connection options, our products can be adapted to a wide range of plumbing applications.

Ductile iron full-flange cross is a pipe fitting used to connect four pipes of equal diameter at right angles. It is commonly used in water supply systems, sewage systems, and industrial applications. The application of ductile iron full flange cross is as follows:

1. Water supply system: The water supply system adopts ductile iron full-flange cross to connect four pipes at right angles. It is used in underground and above ground water supply systems.

2. Sewage system: all flanges of ductile iron are crossed for the sewage system, connecting four pipes at right angles. It is used in underground and above ground sewage systems.

3. Industrial application: Ductile iron full flange cross is used in various industrial applications, such as chemical plants, oil refineries and power plants. In these applications, it is used to connect four pipes at right angles.

4. Irrigation system: Ductile iron All flanges are crossed for irrigation system, connecting four pipes at right angles. It is used in underground and above ground irrigation systems.

5. HVAC system: Ductile iron All flanges are crossed for HVAC system, connecting four pipes at right angles. It is used in commercial and residential HVAC systems.

In short, the ductile iron all flange crossover is a versatile pipe fitting that is used in a variety of applications. It is known for its durability, strength and corrosion resistance. Its application in water supply systems, sewage systems, industrial applications, irrigation systems and HVAC systems makes it an important part of the pipeline and plumbing industry.

Our ductile iron full-flanged crossover is suitable for both above and below ground installations, providing superior performance and reliability. With its stylish and modern design, our products will integrate seamlessly into your plumbing system, ensuring a professional and polished look.

Trust our expertise and experience to provide you with the best solution for your pipeline needs. Contact us to learn more about our ductile iron full flange cross and how it can benefit your business.

Production Workshop

Company development direction: Strive to become a leader in specialized manufacturing and technological innovation of sealing products for water and thermal pipelines in the pipeline interface sealing industry.

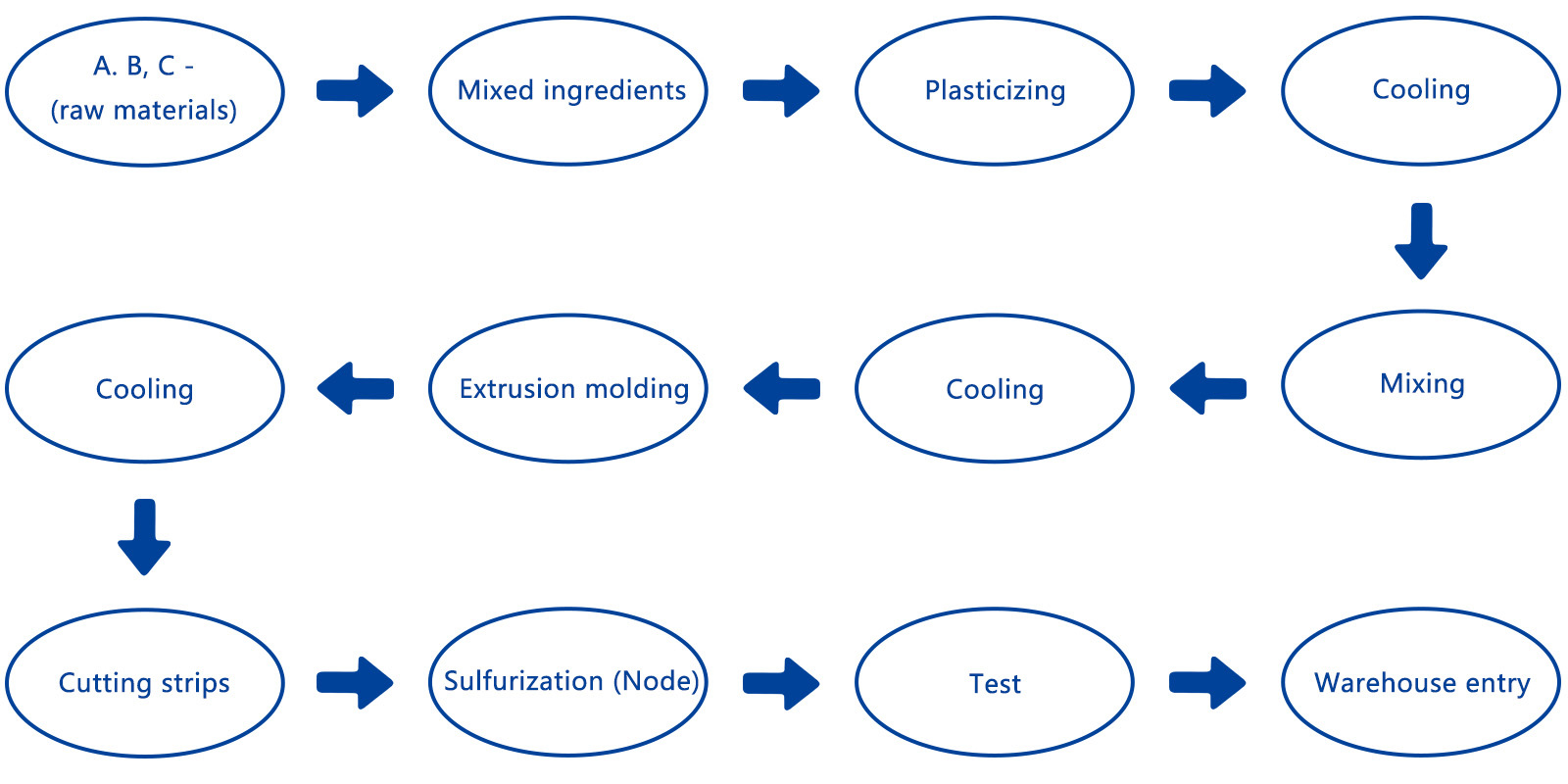

Production Process

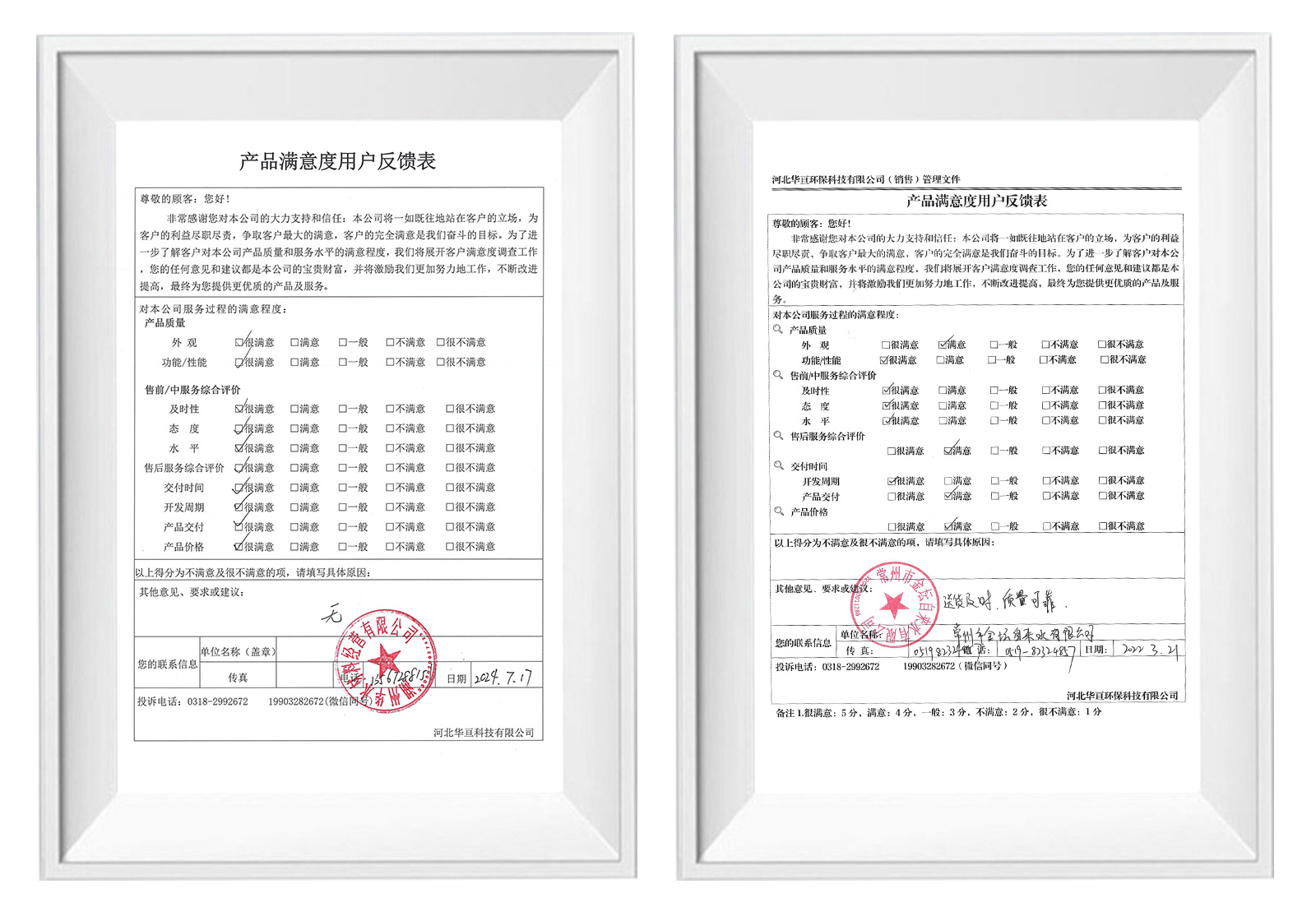

Qualification Certificate

Buyer Reviews

Engineering Case

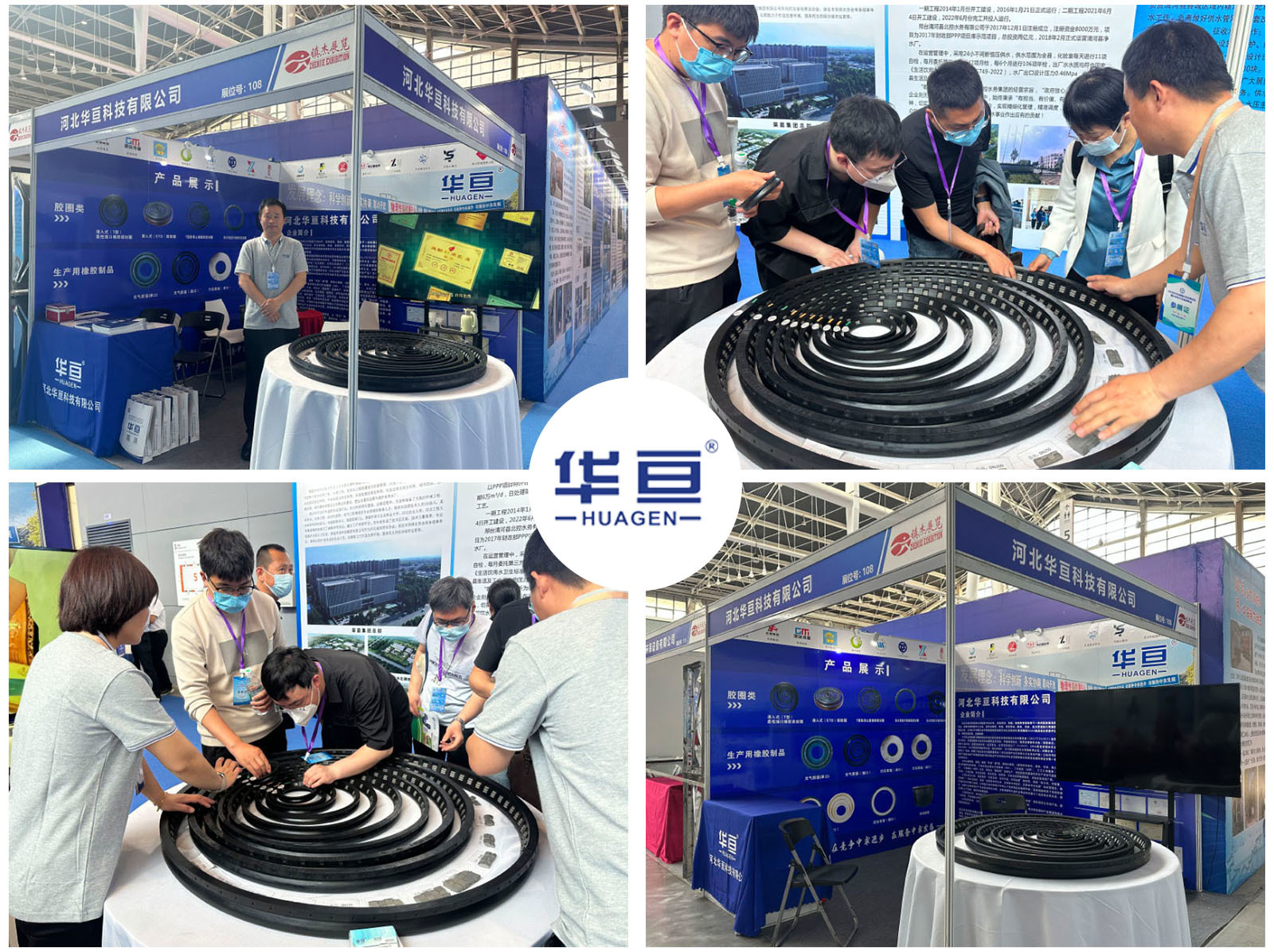

Exhibition Team

Logistics Delivery

Factory Panorama

Application Scenarios

Common Problem

★ 1. Cracks and fractures: Rubber rings may experience cracks and fractures during use due to stress or aging.

The treatment method can be to repair or replace rubber rings with cracks and fractures. Rubber patches or glue can be used for reinforcement during repair.

★ 2. Deformation and hardening: Rubber rings may undergo deformation and hardening when used for a long time or exposed to external environments such as high temperatures and chemicals.

The solution can be to replace the deformed and hardened rubber rings. In addition, appropriate maintenance measures can be taken, such as avoiding exposure to extreme temperatures and using suitable lubricants, to extend the service life of the rubber ring.

★ 3. Corrosion and aging: Rubber rings can experience corrosion and aging after prolonged use or exposure to corrosive effects such as chemicals and oxygen.

The solution can be to replace the rubber rings that have corrosion and aging. In addition, appropriate maintenance measures can be taken, such as storing in a dry, cool, and well ventilated environment, to extend the service life of the rubber ring.

★ 4. Friction damage: Rubber rings may experience friction damage when in contact or friction with other hard objects.

The treatment method can be to repair or replace the rubber ring with friction damage. Rubber patches or glue can be used for repair.

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!