Slide-in (T-shaped) flexible interface rubber seal ring T-DN200

Support Customized Processing

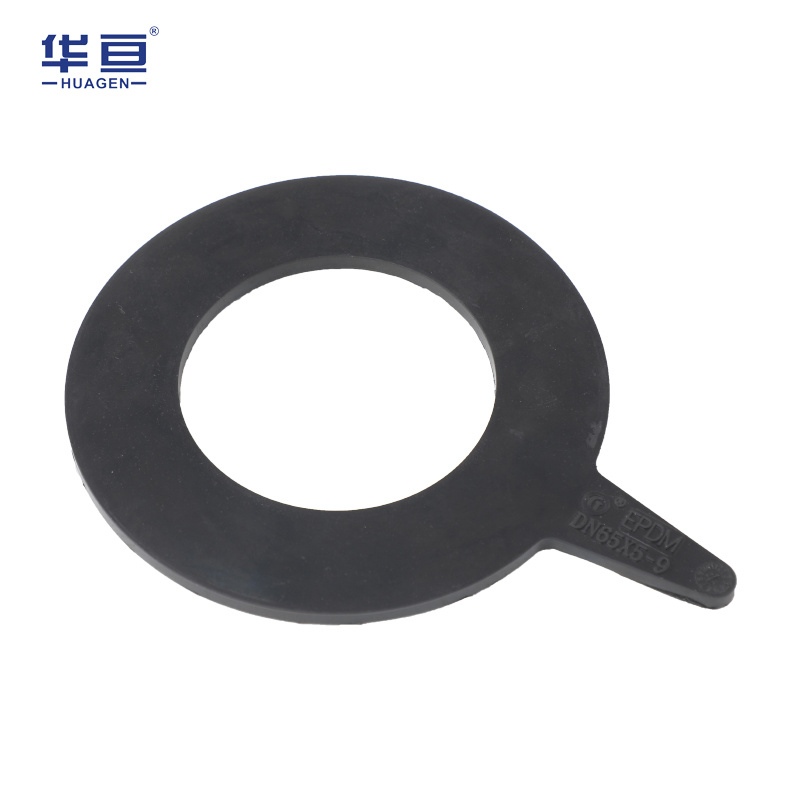

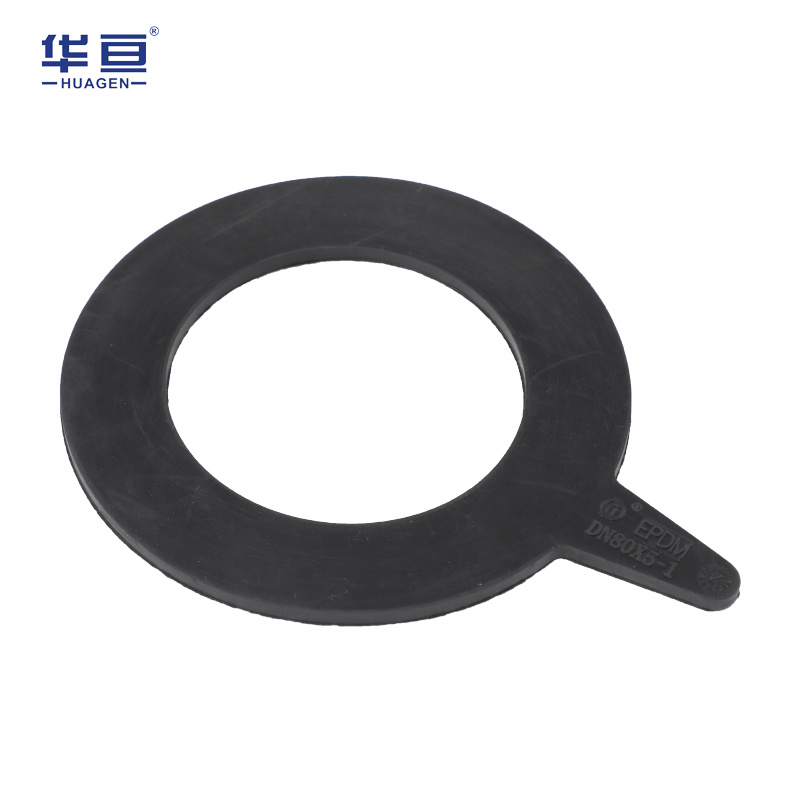

The "Hua Gen" brand sliding T(DN80-DN2000) and flange gasket (DN80-DN2000) series rubber sealing rings for water supply and drainage pipelines produced by our company according to GB 13295 national standard have been matched with many water supply projects in China.

MOQ:

1000

- Commodity name: Slide-in (T-shaped) flexible interface rubber seal ring T-DN200

Support:

hgxs@hbhuagen.com

- Product Description

-

The "Hua Gen" brand sliding T(DN80-DN2000) and flange gasket (DN80-DN2000) series rubber sealing rings for water supply and drainage pipelines produced by our company according to GB 13295 national standard have been matched with many water supply projects in China.

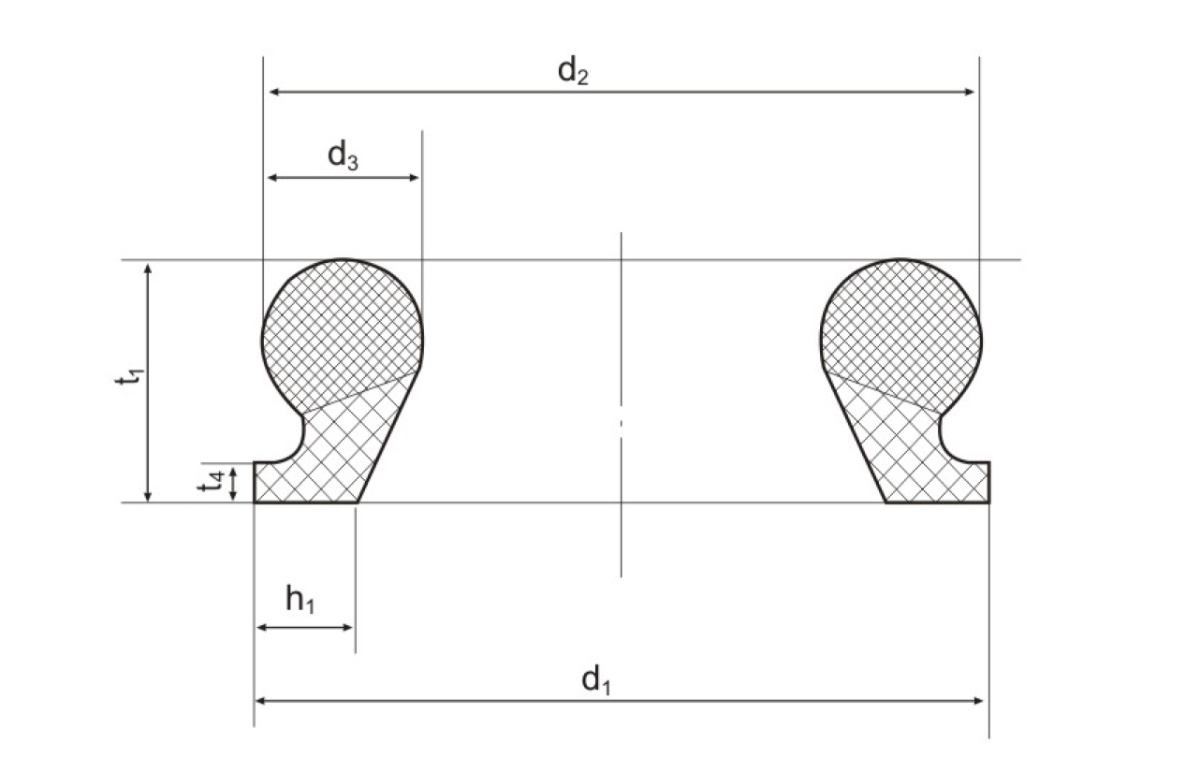

Product Parameters

Specifications d1 d2 d3 h1 t1 t4 Net weight (kg) DN80 126±1 124±1 16 0.5 10±0.3 26 5 0.4-0.2 0.131 DN100 146±1 144±1 16 0.5 10±0.3 26 5 0.4-0.2 0.15 DN125 173±1 171±1 16 0.5 10±0.3 26 5 0.4-0.2 0.19 DN150 200±1.5 198±1.5 16 0.5 10±0.3 26 5 0.4-0.2 0.223 DN200 256±1.5 254±1.5 18 0.5 11±0.3 30 6 0.4-0.2 0.36 DN250 310±1.5 308±1.5 18 0.5 11±0.3 32 6 0.4-0.2 0.485 DN300 366±1.5 364±1.5 20 0.5 12±0.3 34 7 0.4-0.2 0.651 DN350 420±2 418±2 20 0.5 12±0.3 34 7 0.4-0.2 0.756 DN400 475±2 473±2 22 0.5 13±0.3 38 8 0.5-0.3 1.042 DN450 532±2.5 528±2.5 23 0.5 13±0.3 38 8 0.5-0.3 1.220 DN500 583±3 581±3 24 0.5 14±0.3 42 9 0.5-0.3 1.583 DN600 692±3 690±1.5 26 0.5 15±0.3 46 10 0.5-0.3 2.178 DN700 809 5-2.5 803±3 33.5 0.5 20±0.3 55 16 0.5-0.3 4.054 DN800 919 5-2.5 913±3.5 35.5 0.5 21±0.3 60 16 0.5-0.3 5.366 DN900 1026 6-2 1020±4 37.5 0.5 22±0.3 65 18 0.5-0.3 6.800 DN1000 1133 7-2 1127±4 39.5 0.5 23±0.3 70 18 0.5-0.3 8.475 DN1100 1242 8-2 1235±5 41.5 0.5 26±0.3 74 20 0.5-0.3 11.5 DN1200 1352 9-2 1345±6 43.5 0.5 27±0.3 78 20 0.5-0.3 12.552 DN1400 15690-6 15490-6 43.5 0.5 270-0.5 80 0-3 20 16.65 DN1600 17850-6 17650-6 45 0.5 290-2.5 84 0-3 25 16.98

Production Workshop

Company development direction: Strive to become a leader in specialized manufacturing and technological innovation of sealing products for water and thermal pipelines in the pipeline interface sealing industry.

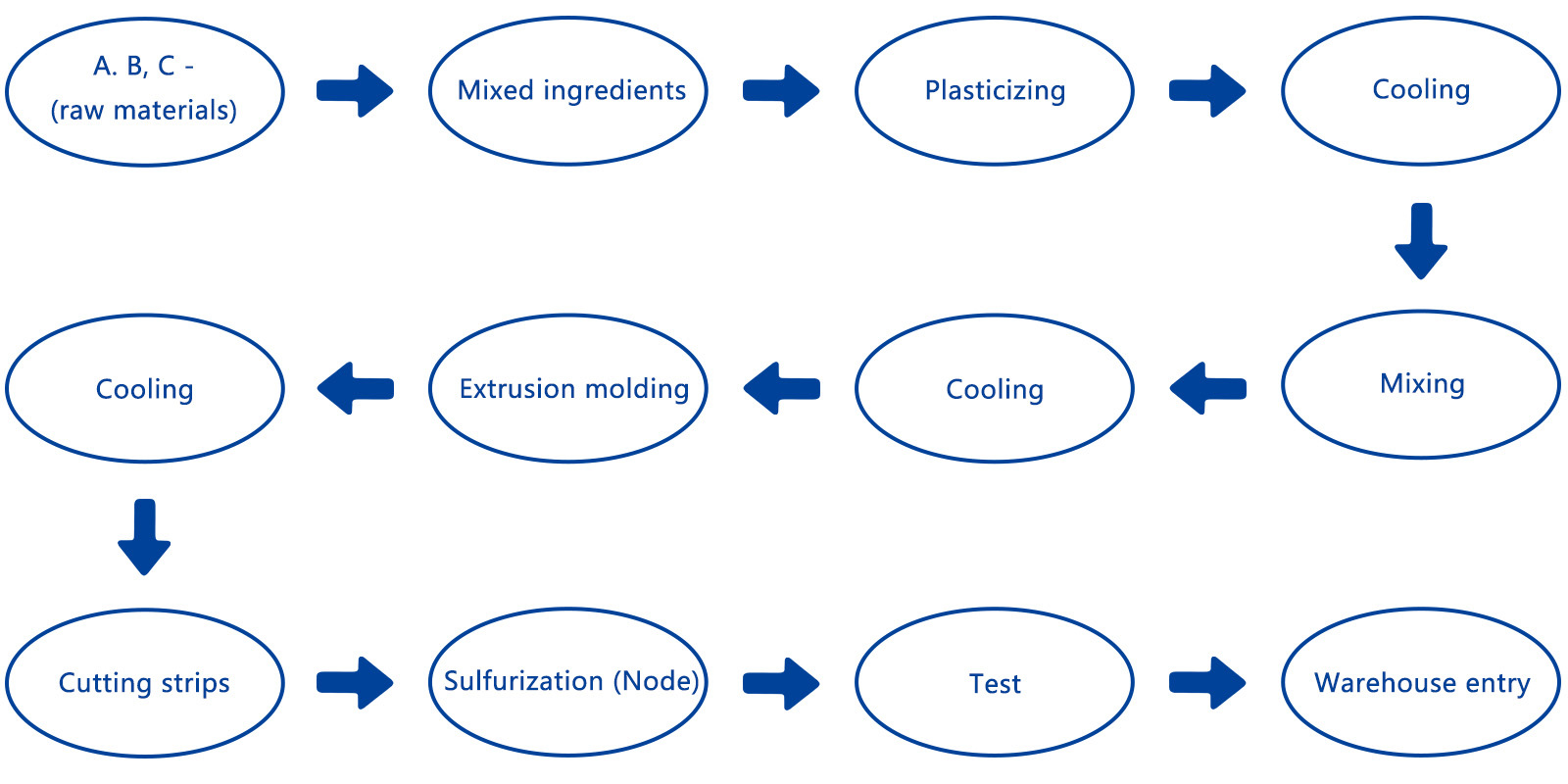

Production Process

Qualification Certificate

Buyer Reviews

Engineering Case

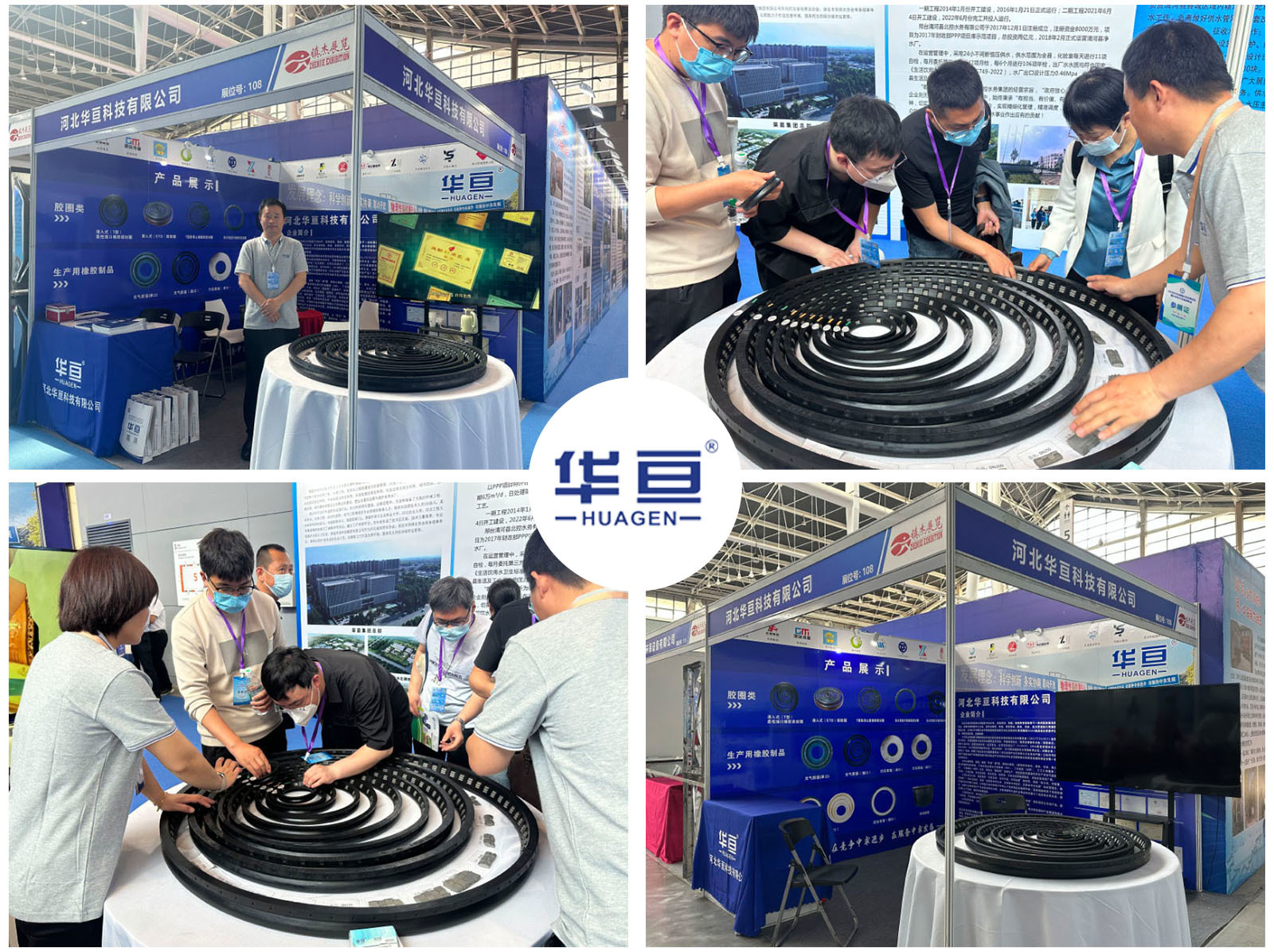

Exhibition Team

Logistics Delivery

Factory Panorama

Application Scenarios

Common Problem

★ 1. Cracks and fractures: Rubber rings may experience cracks and fractures during use due to stress or aging.

The treatment method can be to repair or replace rubber rings with cracks and fractures. Rubber patches or glue can be used for reinforcement during repair.

★ 2. Deformation and hardening: Rubber rings may undergo deformation and hardening when used for a long time or exposed to external environments such as high temperatures and chemicals.

The solution can be to replace the deformed and hardened rubber rings. In addition, appropriate maintenance measures can be taken, such as avoiding exposure to extreme temperatures and using suitable lubricants, to extend the service life of the rubber ring.

★ 3. Corrosion and aging: Rubber rings can experience corrosion and aging after prolonged use or exposure to corrosive effects such as chemicals and oxygen.

The solution can be to replace the rubber rings that have corrosion and aging. In addition, appropriate maintenance measures can be taken, such as storing in a dry, cool, and well ventilated environment, to extend the service life of the rubber ring.

★ 4. Friction damage: Rubber rings may experience friction damage when in contact or friction with other hard objects.

The treatment method can be to repair or replace the rubber ring with friction damage. Rubber patches or glue can be used for repair.

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!