Wide range of flexible joints

Support Customized Processing

Universal straight coupling-the perfect solution for all your pipeline needs! If you want to connect pipes of different materials, this coupling is your best choice. Made of high-quality materials, it provides unparalleled durability and strength, while also providing a long-lasting seal.

MOQ:

1000

- Commodity name: Wide range of flexible joints

Support:

hgxs@hbhuagen.com

- Product Description

-

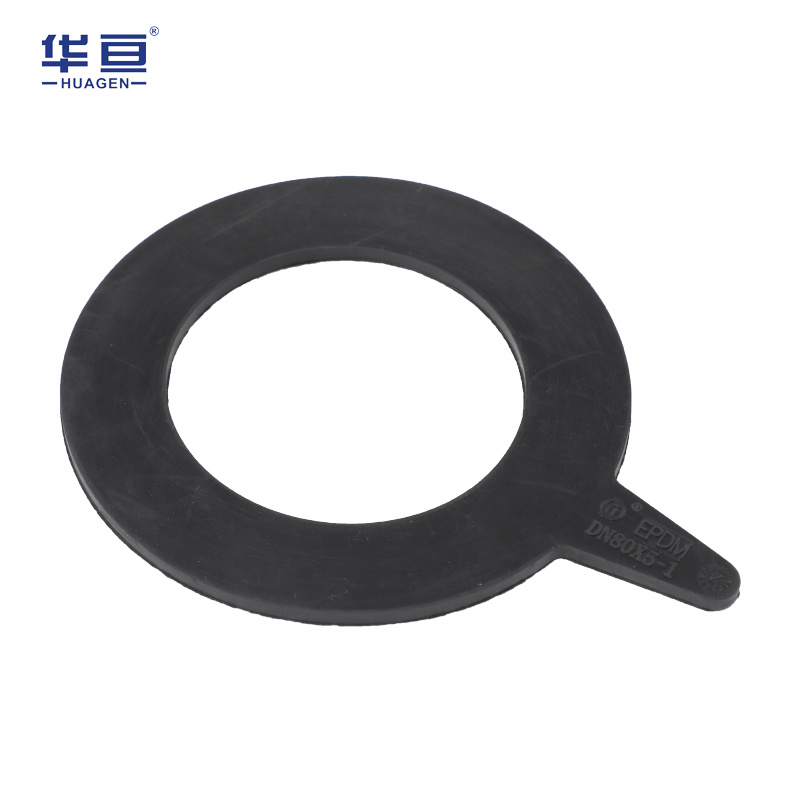

About light universal wide tolerance coupling PN10 PN16:

The wide tolerance universal coupling includes flexible fittings that allow expansion, contraction and movement, and a fully constrained version, which eliminates the need for expensive thrust blocks to accommodate the forces generated by the internal pressure of the pipe.

Universal straight coupling-the perfect solution for all your pipeline needs! If you want to connect pipes of different materials, this coupling is your best choice. Made of high-quality materials, it provides unparalleled durability and strength, while also providing a long-lasting seal.

The universal direct-coupled design seamlessly blends into your plumbing system, ensuring watertight connections every time. No additional tools are needed and installation is quick and hassle-free. The design has two female connectors, please be sure to check the individual size of the universal coupling to make sure it is suitable for your project.

Made from durable and sturdy materials, this coupling provides superior strength and longevity, resistance to wear or damage from external factors such as weather or exposure to chemicals. In addition, it is corrosion resistant and maintains its smooth appearance for many years.

This coupling is ideal for use in a range of applications, including commercial, industrial and residential environments. It is very suitable for use in various plumbing projects, and you can rest assured that it will serve you in the next few years.

The universal straight coupling is compatible with pipes of various materials, making it the perfect choice for any application. This makes it a versatile and cost-effective solution that saves you time and money.

The coupling has a design that is easy to install and remove, making it an ideal tool for expert contractors and do-it-yourself. With its no fuss installation, you can get the job done quickly without any stress, ensuring an efficient piping system.

Features

Completely corrosion-resistant structure

Internal and external fusion bonded epoxy coating

Structure Design of Light Ductile Iron

Wide joint range

Cold galvanized carbon steel fasteners

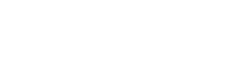

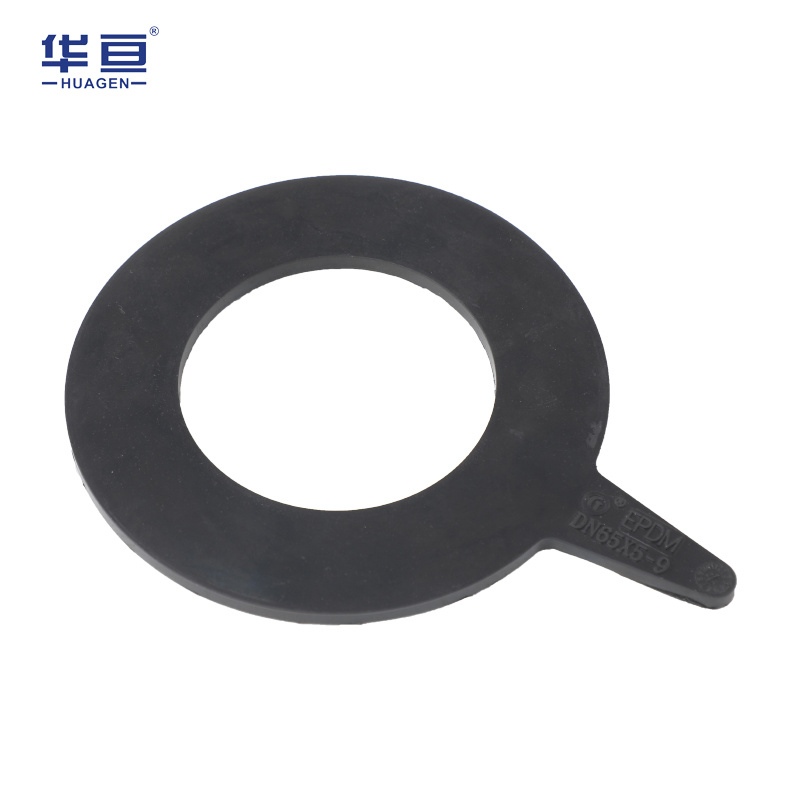

WRAS certified EPDM gasket

Specifications

Type test: EN14525/BS8561

Elastomer: EN681-2

Light Rail: EN1563 EN-GJS-450-10

Coating: WIS4-52-01

Drilling specifications: EN1092-2

PN10/16

DI steel pipe connection

Suitable for water and neutral liquid (sewage) applications

Operating temperature up to 70°C

Product Details

Production Workshop

Company development direction: Strive to become a leader in specialized manufacturing and technological innovation of sealing products for water and thermal pipelines in the pipeline interface sealing industry.

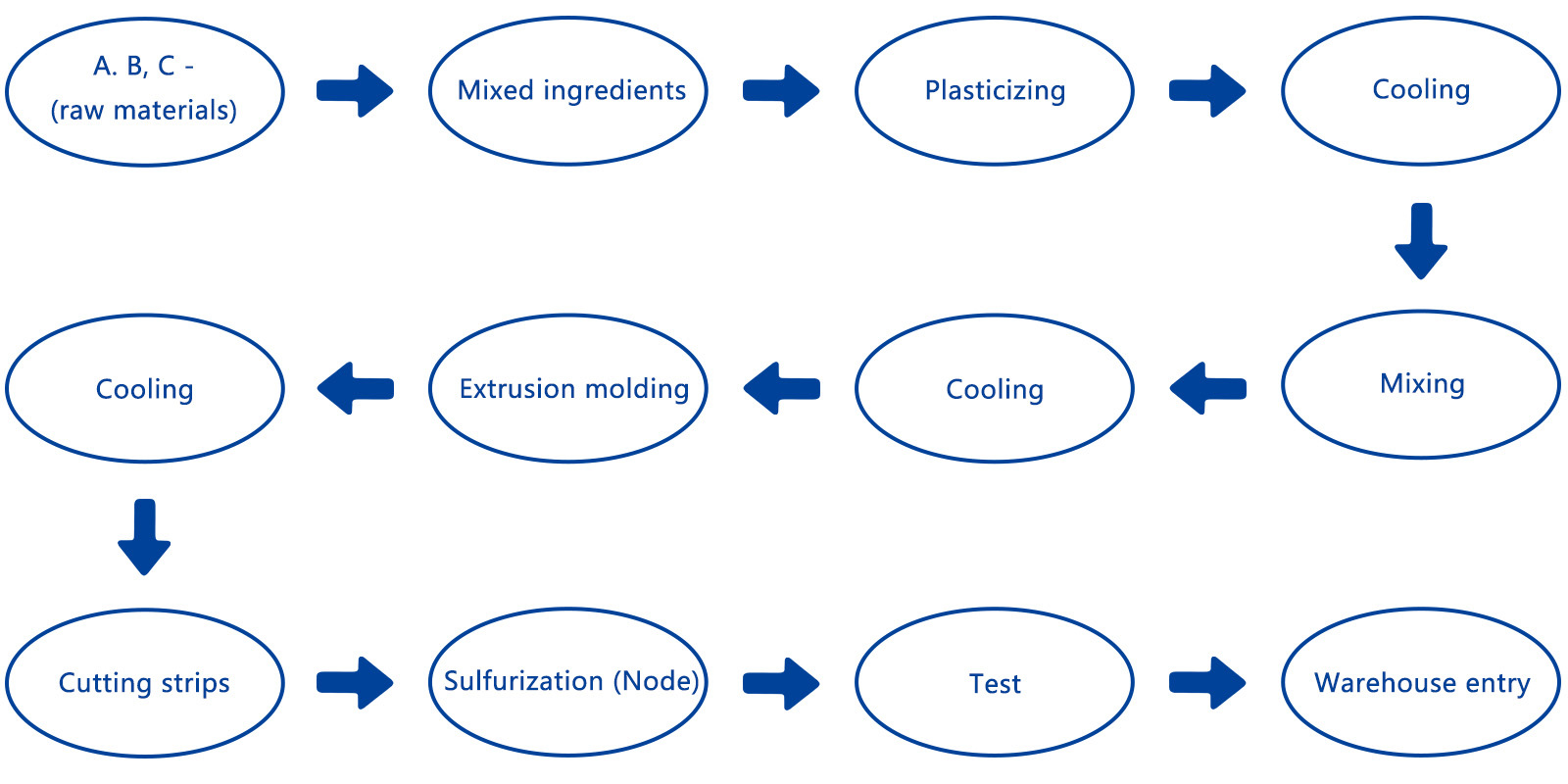

Production Process

Qualification Certificate

Buyer Reviews

Engineering Case

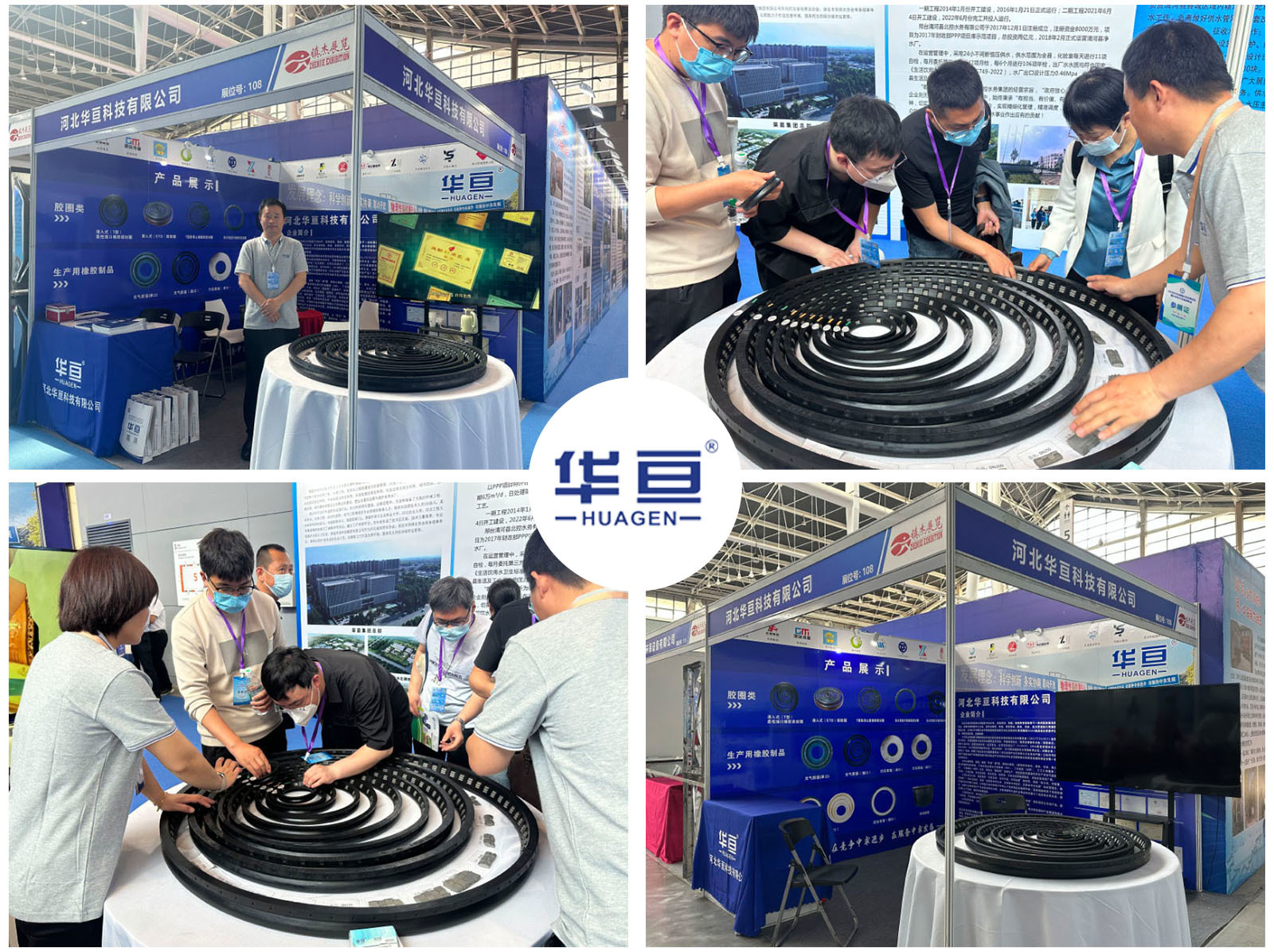

Exhibition Team

Logistics Delivery

Factory Panorama

Application Scenarios

Common Problem

★ 1. Cracks and fractures: Rubber rings may experience cracks and fractures during use due to stress or aging.

The treatment method can be to repair or replace rubber rings with cracks and fractures. Rubber patches or glue can be used for reinforcement during repair.

★ 2. Deformation and hardening: Rubber rings may undergo deformation and hardening when used for a long time or exposed to external environments such as high temperatures and chemicals.

The solution can be to replace the deformed and hardened rubber rings. In addition, appropriate maintenance measures can be taken, such as avoiding exposure to extreme temperatures and using suitable lubricants, to extend the service life of the rubber ring.

★ 3. Corrosion and aging: Rubber rings can experience corrosion and aging after prolonged use or exposure to corrosive effects such as chemicals and oxygen.

The solution can be to replace the rubber rings that have corrosion and aging. In addition, appropriate maintenance measures can be taken, such as storing in a dry, cool, and well ventilated environment, to extend the service life of the rubber ring.

★ 4. Friction damage: Rubber rings may experience friction damage when in contact or friction with other hard objects.

The treatment method can be to repair or replace the rubber ring with friction damage. Rubber patches or glue can be used for repair.

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!