Ductile iron flange reducer

Support Customized Processing

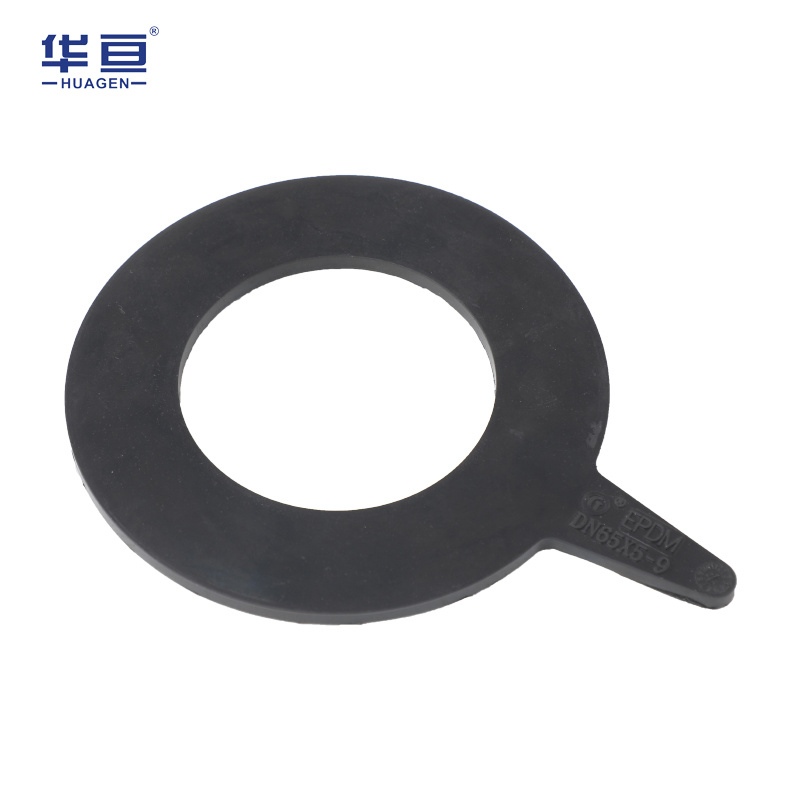

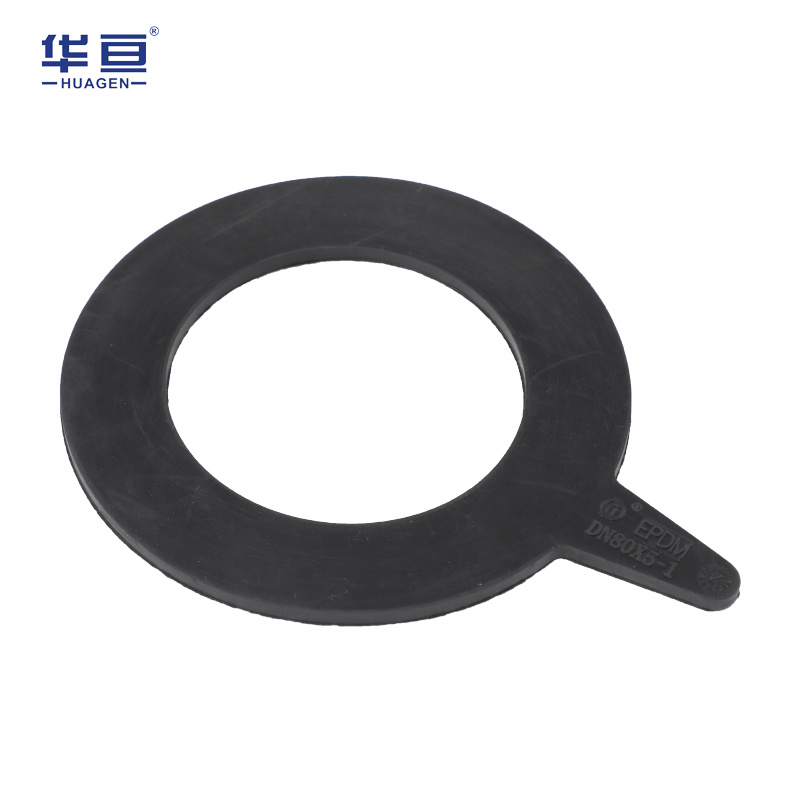

The ductile iron flange reducer is a pipe fitting used to connect two pipes of different sizes. It is made of ductile iron, which is a cast iron treated with magnesium to make it more flexible and durable. One side of the reducer has a flange end that can be bolted to a flange on a pipe, and the other side has a smaller end that can be connected to a smaller pipe.

MOQ:

1000

- Commodity name: Ductile iron flange reducer

Support:

hgxs@hbhuagen.com

- Product Description

-

1. Type test: EN14525/BS8561

3. Double iron: EN1563 EN-GJS-450-10

4. Coating: WIS4-52-01

5. Standard: EN545/ISO2531

6. Drilling specifications: EN1092-2

Ductile iron flange reducer is a pipe fitting used to connect two pipes of different sizes. It is made of ductile iron, which is a kind of cast iron treated with magnesium to make it more flexible and durable. One side of the reducer has a flange end that can be bolted to a flange on a pipe, and the other side has a smaller end that can be connected to a smaller pipe. This allows for a smooth transition between two pipes of different sizes while maintaining the integrity of the pipe. Ductile iron flange reductants are commonly used in water and sewage systems and in industrial applications.

The ductile iron flange reducer is a pipe fitting used to connect two pipes of different sizes. It is made of ductile iron, which is a cast iron treated with magnesium to make it more flexible and durable. The flange design of the reducer is easy to install and remove, making it a popular choice for industrial applications. Reducers are available in various sizes and pressure ratings to meet the specific needs of different applications. It is commonly used in water and wastewater treatment plants, chemical processing plants, and oil and gas refineries. Ductile iron flanged reducers are known for their high strength, corrosion resistance and long service life, making them a reliable and cost-effective solution for piping systems.

Ductile iron flange reducers are usually used in piping systems to connect pipes of different sizes. They are designed to reduce the diameter of the pipe and maintain a smooth flow of fluid or gas. Ductile iron is a strong and durable material that can withstand high pressures and temperatures, making it ideal for use in industrial applications.

Some common applications of ductile iron flange reducer include

1. Water treatment plant: Ductile iron flange reducer is used in water treatment plants to connect pipes of different sizes and maintain consistent water flow.

2. Oil and gas industry: Ductile iron flange reducers are used in oil and gas pipelines to reduce the diameter of the pipeline and maintain a consistent oil or gas flow.

3. Chemical processing plant: Ductile iron flange reducer is used in chemical processing plants to connect pipes of different sizes and maintain a consistent chemical flow.

4. HVAC system: Ductile iron flange reducer is used in HVAC system to connect pipes of different sizes and maintain consistent air flow.

5. Mining industry: Ductile iron flange reducers are used in mining operations to connect pipes of different sizes and maintain a consistent flow of water or chemicals.

Overall, ductile iron flanged reducers are a versatile and reliable component in many industrial applications, providing a cost-effective solution for connecting pipes of different sizes and maintaining consistent fluid or gas flow.

Production Workshop

Company development direction: Strive to become a leader in specialized manufacturing and technological innovation of sealing products for water and thermal pipelines in the pipeline interface sealing industry.

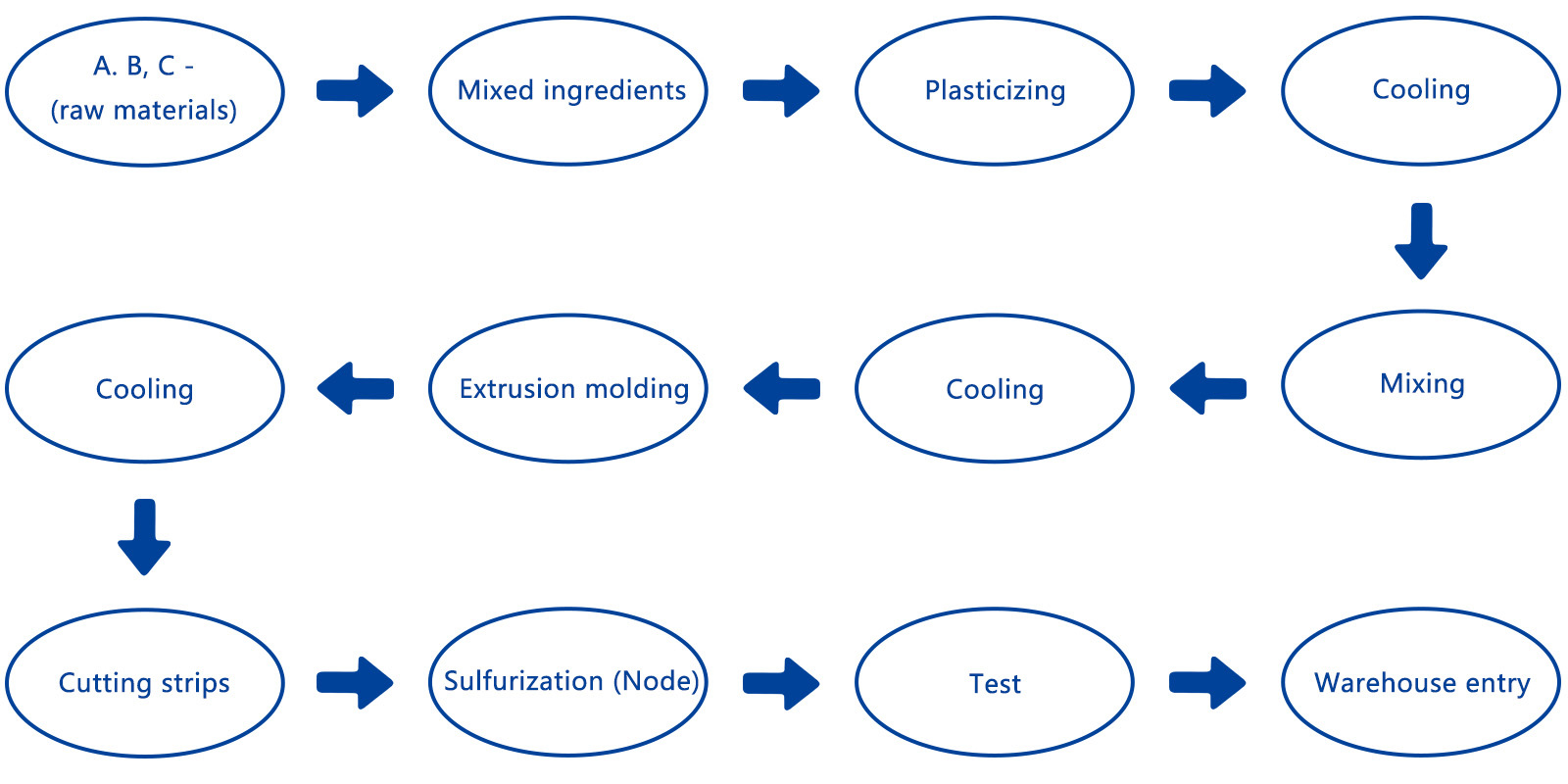

Production Process

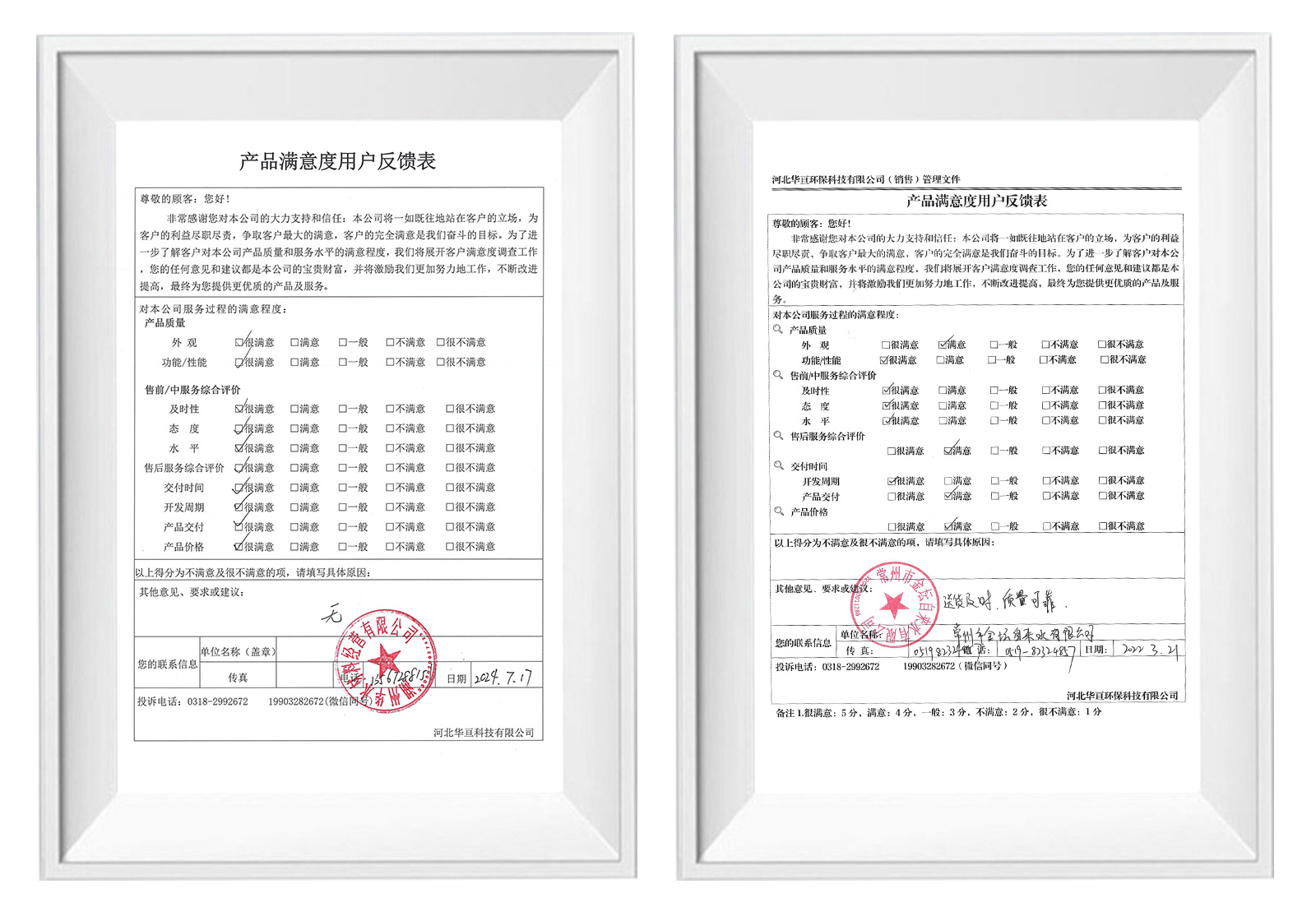

Qualification Certificate

Buyer Reviews

Engineering Case

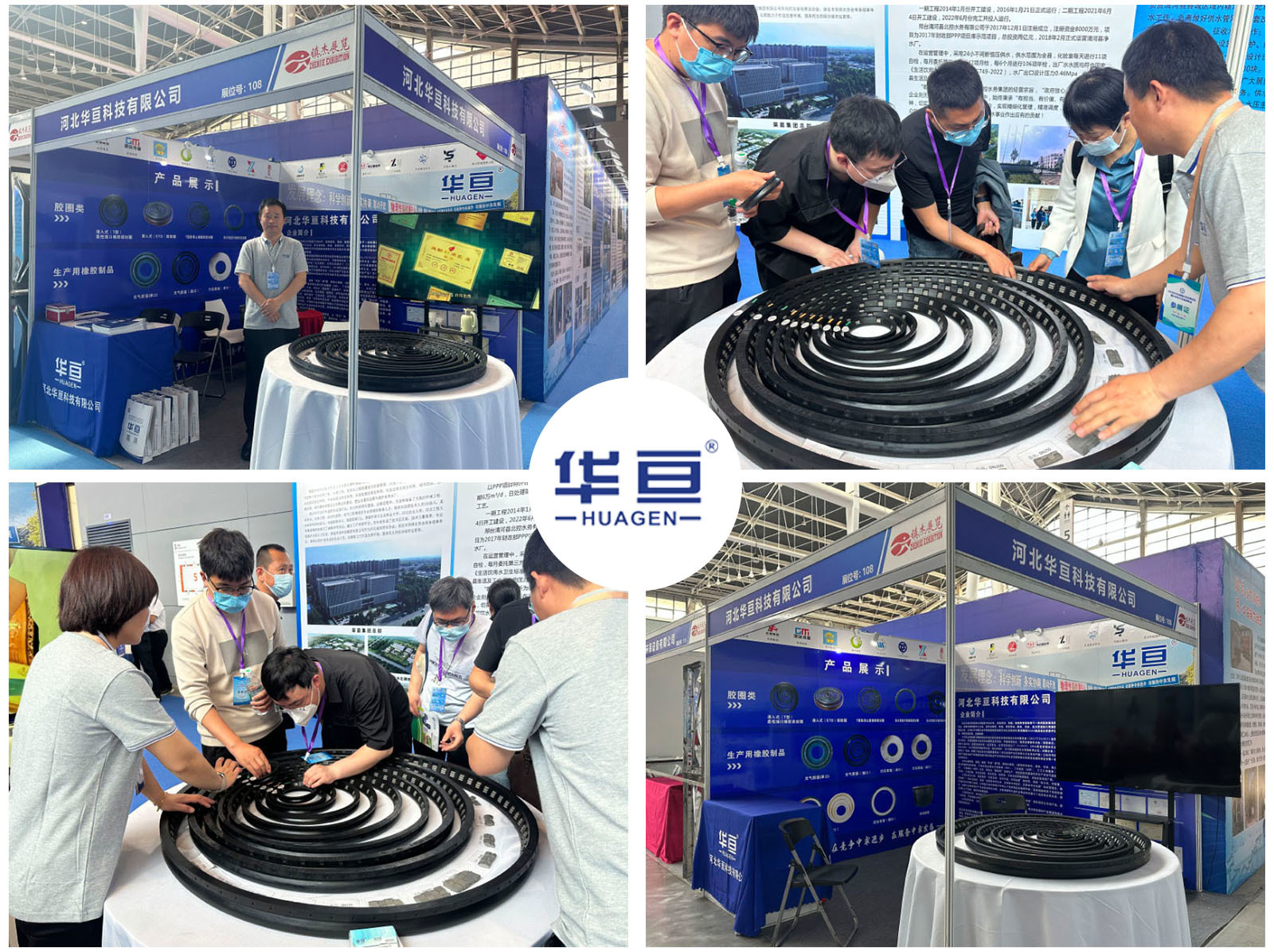

Exhibition Team

Logistics Delivery

Factory Panorama

Application Scenarios

Common Problem

★ 1. Cracks and fractures: Rubber rings may experience cracks and fractures during use due to stress or aging.

The treatment method can be to repair or replace rubber rings with cracks and fractures. Rubber patches or glue can be used for reinforcement during repair.

★ 2. Deformation and hardening: Rubber rings may undergo deformation and hardening when used for a long time or exposed to external environments such as high temperatures and chemicals.

The solution can be to replace the deformed and hardened rubber rings. In addition, appropriate maintenance measures can be taken, such as avoiding exposure to extreme temperatures and using suitable lubricants, to extend the service life of the rubber ring.

★ 3. Corrosion and aging: Rubber rings can experience corrosion and aging after prolonged use or exposure to corrosive effects such as chemicals and oxygen.

The solution can be to replace the rubber rings that have corrosion and aging. In addition, appropriate maintenance measures can be taken, such as storing in a dry, cool, and well ventilated environment, to extend the service life of the rubber ring.

★ 4. Friction damage: Rubber rings may experience friction damage when in contact or friction with other hard objects.

The treatment method can be to repair or replace the rubber ring with friction damage. Rubber patches or glue can be used for repair.

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!