Removable connector (Type 1)

Support Customized Processing

The disassembly joint is a pipe assembly specially designed to facilitate the installation, maintenance and replacement of pipe components such as valves, pumps and flanges. Its unique design allows for easy and efficient disassembly of pipe sections, without the need for cutting or welding. This saves time, improves safety, and reduces the costs involved in pipeline maintenance projects.

MOQ:

1000

- Commodity name: Removable connector (Type 1)

Support:

hgxs@hbhuagen.com

- Product Description

-

Introduction

Lucile Iron GG50,GJS500-7,GGG40

Size: DN40-DN2800

Pressure: PN10,PN16,PN25,PN40

Pressure test: 15Bar,24Bar,37.5bar,60Bar.

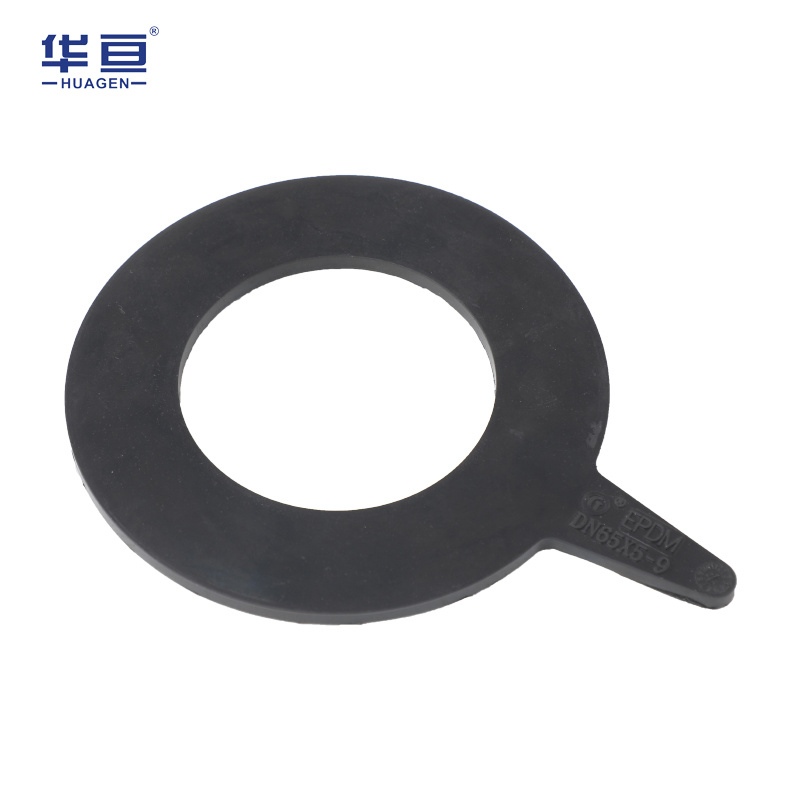

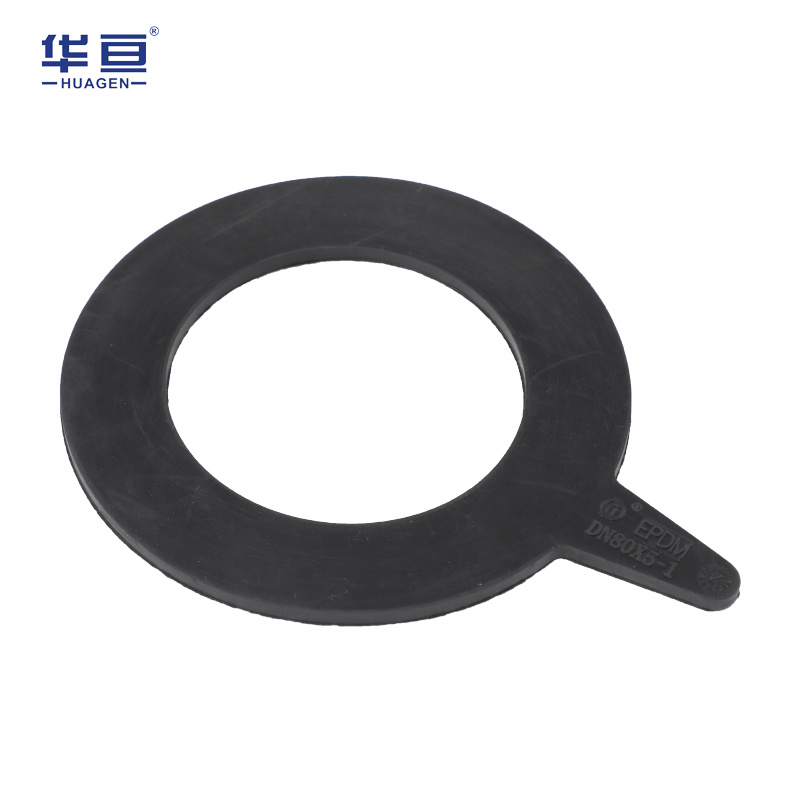

EPDM,NBR rubber seals comply with EN681 and ASTM d2000.

Painting: RAL5017 FBE coating, minimum, coating thickness 200 μm.

End connection: Flanged end, DI pipe

The disassembly joint is a pipe assembly specially designed to facilitate the installation, maintenance and replacement of pipe components such as valves, pumps and flanges. Its unique design allows for easy and efficient disassembly of pipe sections, without the need for cutting or welding. This saves time, improves safety, and reduces the costs involved in pipeline maintenance projects.

The disassembly joint is made of high-quality materials, which can withstand harsh environmental conditions and provide reliable performance. Its rugged construction ensures longevity, while its innovative design makes installation and removal quick and easy.

The disassembly joint is a highly customizable product that can be configured to meet the specific needs of various pipeline applications. In a range of sizes, materials, and pressure ratings, this versatile product is the ultimate solution for pipe installation and maintenance.

The disassembly joint is also designed with some features to make it easy to install and maintain. With its unique flange design and adjustable bolts, the product is highly adaptable and can be easily installed into existing piping systems. In addition, its low friction sliding surface ensures that the joints remain flexible and easy over time.

Overall, disassembly joints are the perfect product for professionals looking to simplify pipe installation and maintenance projects. With its innovative design, high quality materials, and extensive customization options, this product is sure to meet the needs of any plumbing application. Therefore, whether it is a new installation or an existing system that needs to be modified, the disassembly joint is the ideal solution.

Features

Completely corrosion-resistant structure

Internal and external fusion bonded epoxy coating

Structure Design of Light Ductile Iron

Wide joint range

Cold galvanized carbon steel fasteners

WRAS certified EPDM gasket

Production Workshop

Company development direction: Strive to become a leader in specialized manufacturing and technological innovation of sealing products for water and thermal pipelines in the pipeline interface sealing industry.

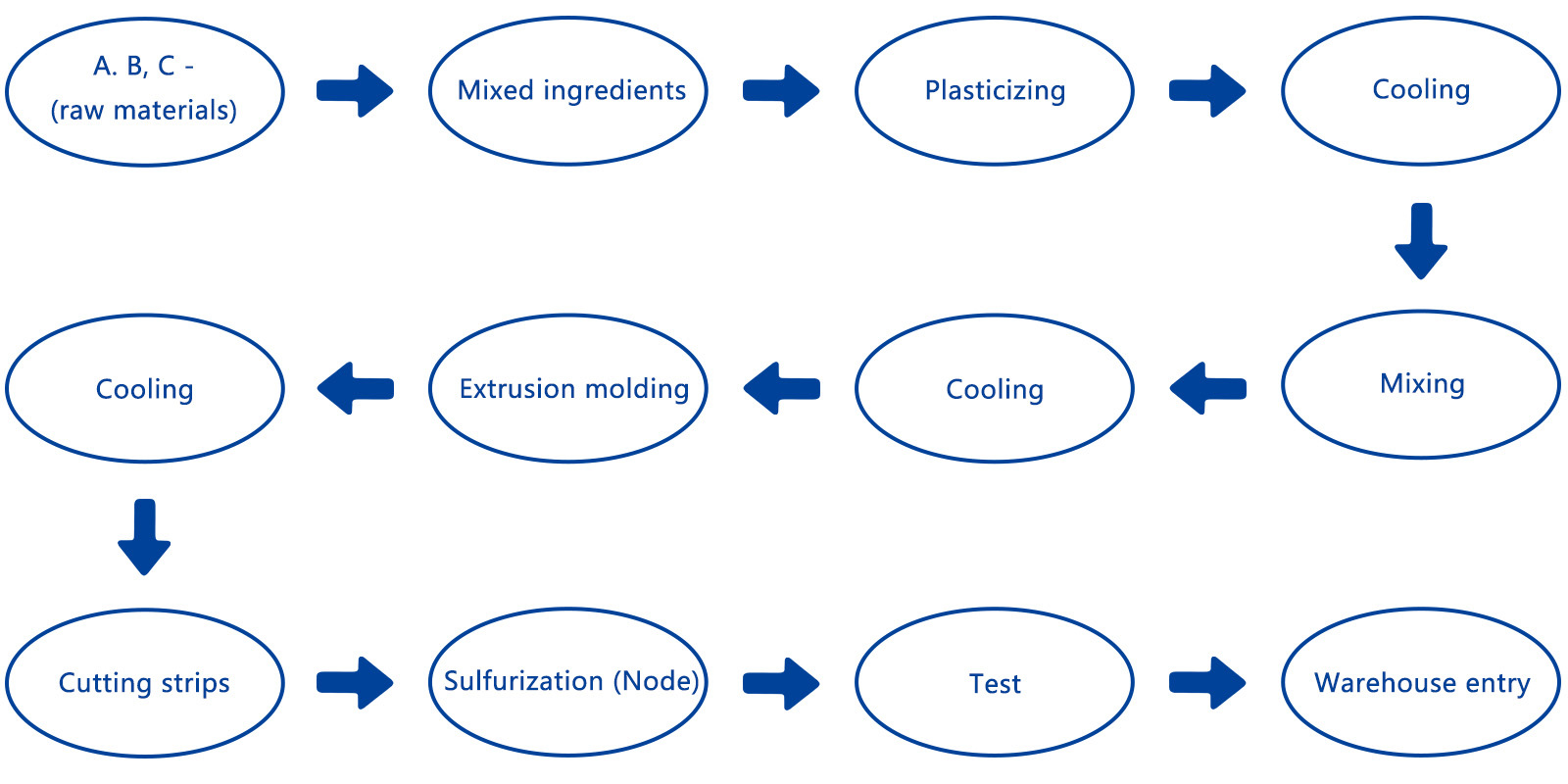

Production Process

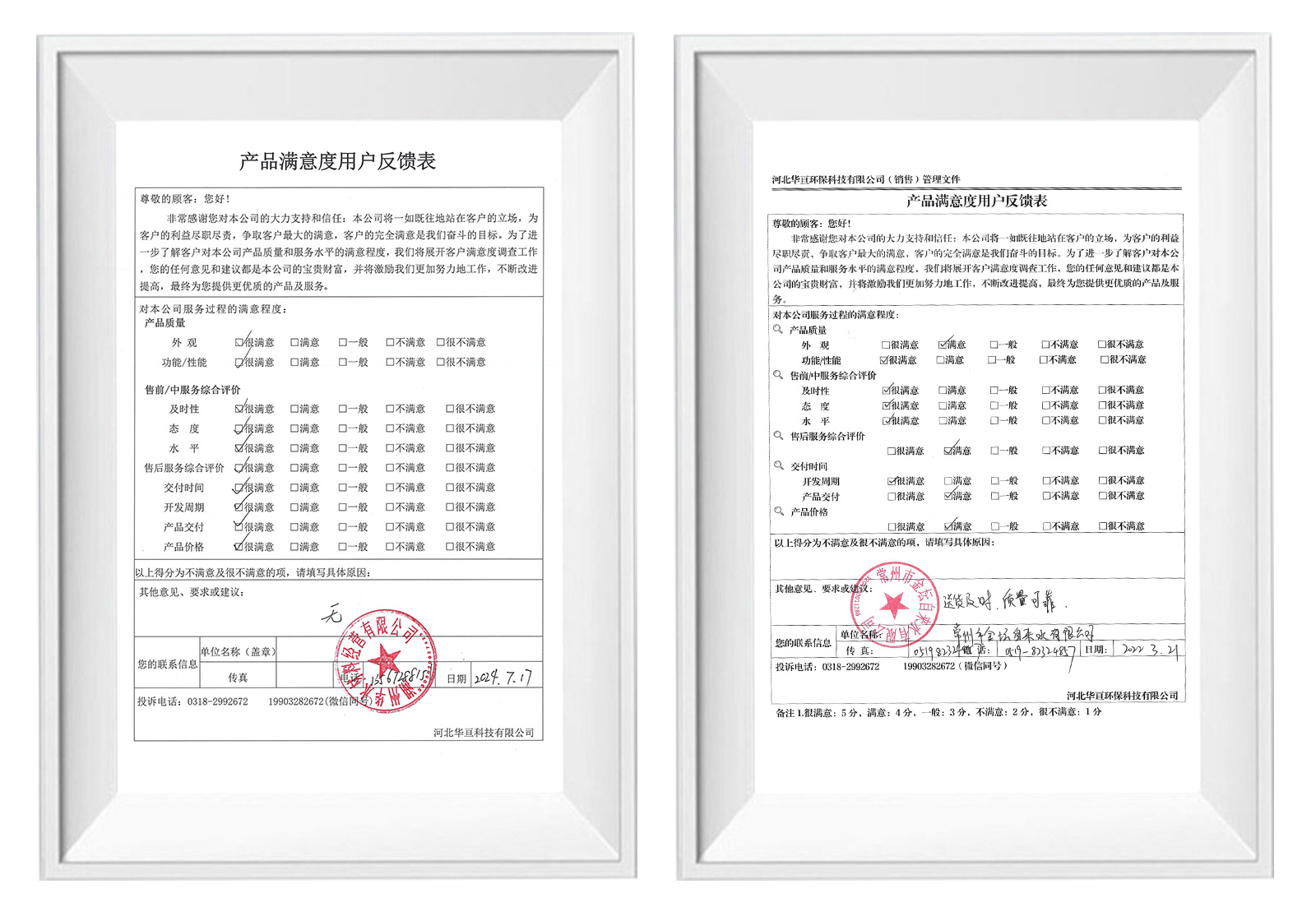

Qualification Certificate

Buyer Reviews

Engineering Case

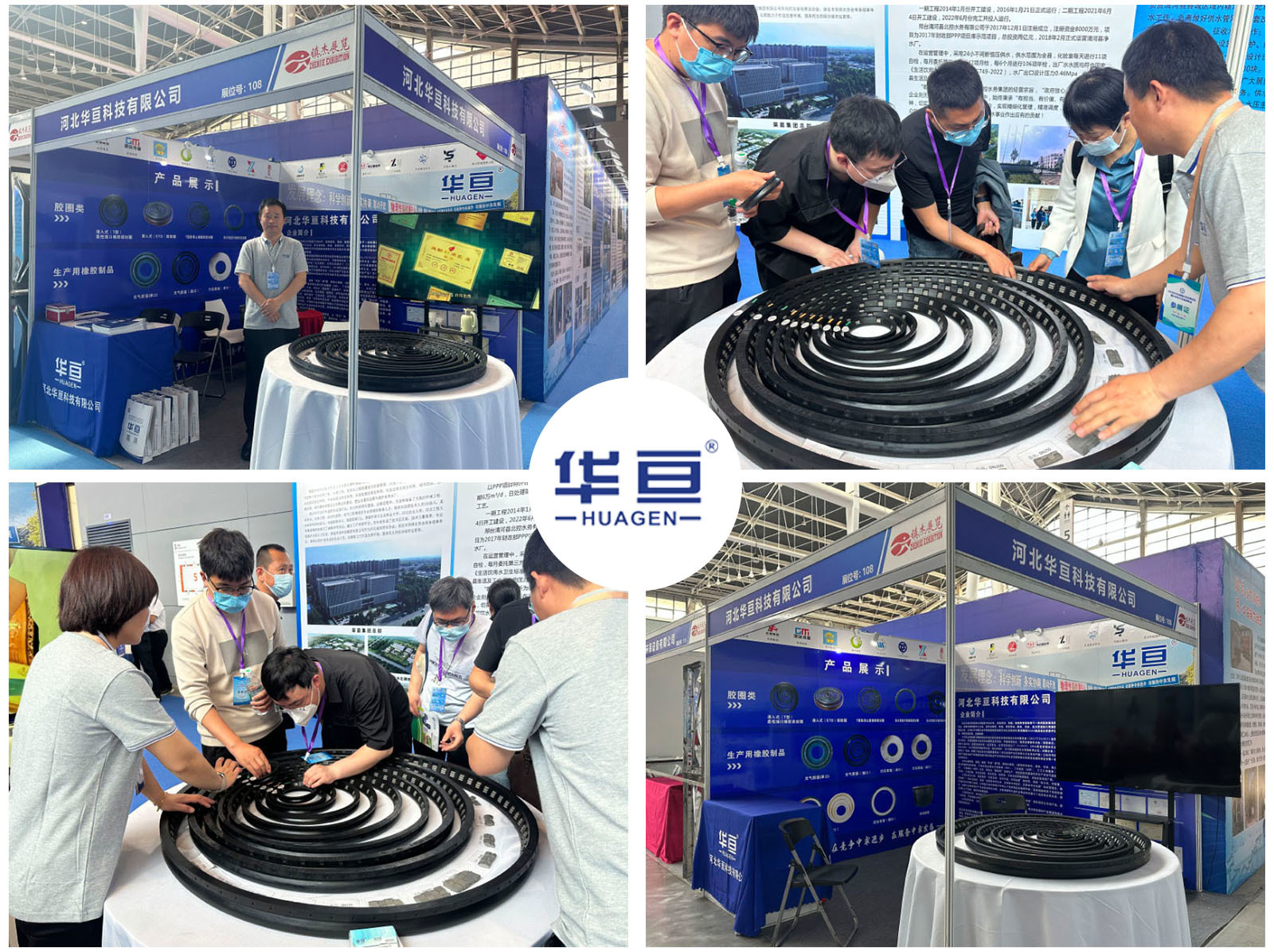

Exhibition Team

Logistics Delivery

Factory Panorama

Application Scenarios

Common Problem

★ 1. Cracks and fractures: Rubber rings may experience cracks and fractures during use due to stress or aging.

The treatment method can be to repair or replace rubber rings with cracks and fractures. Rubber patches or glue can be used for reinforcement during repair.

★ 2. Deformation and hardening: Rubber rings may undergo deformation and hardening when used for a long time or exposed to external environments such as high temperatures and chemicals.

The solution can be to replace the deformed and hardened rubber rings. In addition, appropriate maintenance measures can be taken, such as avoiding exposure to extreme temperatures and using suitable lubricants, to extend the service life of the rubber ring.

★ 3. Corrosion and aging: Rubber rings can experience corrosion and aging after prolonged use or exposure to corrosive effects such as chemicals and oxygen.

The solution can be to replace the rubber rings that have corrosion and aging. In addition, appropriate maintenance measures can be taken, such as storing in a dry, cool, and well ventilated environment, to extend the service life of the rubber ring.

★ 4. Friction damage: Rubber rings may experience friction damage when in contact or friction with other hard objects.

The treatment method can be to repair or replace the rubber ring with friction damage. Rubber patches or glue can be used for repair.

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!